Fun fact: from 40,000 feet, you can see Indianapolis and Chicago at the same time.

That’s the Windy City and its southern suburbs at top left, about 150 miles distant, and downtown Indy at bottom-center. Photographed after flying out of St. Louis.

On a recent visit to Chicago, I was shocked to see that the General Automation, Inc. building (3300 W. Oakton Street at McCormick) was gone. In its place, a generic big box style store selling flooring.

General Automation’s building was one of the north shore’s most distinctive bits of Mid-Century design. It encompassed 75,000 square feet of offices and factory floor for a company that produced precision metal fabrications – machine parts, screws, etc.

Most of the architectural interest was in the curved office section facing Oakton. Concrete piers and panels framed pyramidal windows, in an elaborately framed facade. At the center, a pod-like vestibule welcomed arrivals to the futuristic building. Concrete pattern block screened the lower levels. The major face of the warehouse was lined with concrete panels, decorated with simple fins and a small incised circle on each panel.

According to the successor firm’s website, the General Automation brand began in 1935. A 1958 obituary for an employee (William Starr) lists the company at 900 N. Franklin Street, near what is now the Brown Line tracks downtown. In the 1960s, they moved to 1755 W. Rosehill Drive, in the former industrial corridor along the UP North Metra tracks.

In 1982, the company moved to its newly constructed digs at Oakton and McCormick. Yep, you read that right: the hyper-futuristic 1960s building is actually a 1980s building, at least according to the Life: Skokie Edition newspaper, which noted the company’s pending move in a November 1981 article. No word on the architect, alas, and no independent confirmation that I’ve been able to locate (I find the 1982 date difficult to reconcile with the building’s architectural style.)

In recent years, the company combined with three others to form HN Precision; the consolidated corporation specializes in precision-milled machine parts, serving a variety of industries including rail, oil and gas, automotive and more. Consolidation among the merged companies began in 2011, and the Skokie location closed circa 2012.

The building was sold at the end of 2013, stripped of its architectural exterior, and reclad to bland blend in with its surroundings.

General Automation, Inc. of Illinois should not be confused with an identically named company which, though based in California, also had significant operations in the Chicagoland area. This other General Automation engineered, sold, managed and maintained computer systems, from 1967 through the 1990s, under their own name and the subsidary California GA Corporation, with offices in Des Plaines and Bensenville. As far as I know, they did not have an awesome Brutalist factory building.

Of interest to industrial fans: the vacant lot across Oakton was once a natural gas facility, including three gasometers dating to 1911. They were demolished in the early 1960s; the site is currently undergoing cleanup of remnant contaminants.

I’d like to introduce the world’s largest integrated steelmaking complex, the ArcelorMittal Indiana Harbor steel works in East Chicago.

I say I’d like to – but it’s just too big. Too much. Too hard to grasp. And more importantly, too tightly sealed to public access.

All I can truly offer is a series of stolen glances, quick flashes gained by trooping doggedly around northwest Indiana over the years, over and over – testing the limits of every road, every shoreline, every park, every overpass, every parking lot. I’ve pushed my zoom lenses and my camera’s sensor to their limits, and probably turned the head of every security guard within a mile of the lake’s edge, for glimpses into this astonishing industrial kingdom of ash and fire.

Here I present the results.

One of the facility’s several blast furnaces, where raw ores – fed in at the top, hence all the conveyor belts – are heated and combined into a liquid metal form. AcelorMittal’s website alternately states that there are 3 or 5 blast furnaces on the site.

I cannot say I understand this place, but I am fascinated by it. Flying over it in Bing’s aerial views, the vast size becomes apparent. Hundreds of acres of buildings, jammed one against the next. In true Chicago fashion, they are enormously long, repeating themselves endlessly bay after bay.

What is now ArcelorMittal Indiana Harbor began over a hundred years ago, as the Inland Steel plant. Inland Steel – now most famous for their landmark Modernist headquarters building in downtown Chicago – was formed in 1893, and began development on the Indiana Harbor Canal site in 1902. The business grew over the next 15 years to include a lease on a Minnesota ore mine and a lake freighter division, ensuring in-house control over supply and shipping of raw materials, an integration strategy that would be completed by World War II’s end and last into the 1990s. Across the 20th century, the plant would continuously expand and modernize, while producing a huge variety of goods – from railroad spikes to World War II materiel. Post-war, a large portion of its output went into automobiles. At its peak, 25,000 people worked at the plant. The company was purchased in 1998, becoming Ispat Inland. Mergers in 2005 and 2007 created ArcelorMittal, an international corporation that is the world’s largest steel company and current owners and operators of the facility.

The huge complex is mostly sited on an artificial peninsula jutting out into Lake Michigan, with the Indiana Harbor Canal running down the middle. Many acres are covered with buildings; the site is also criss-crossed with railroad tracks, roads, overpasses, material storage lots, and a huge variety of industrial structures. In the 2010 photograph above, the now-demolished Cline Avenue – aka Indiana State Road 912 – snakes its way around the inland portion of the facility. Marktown is visible at lower left; just out of the frame to the left is the giant BP refinery at Whiting.

The site is also a bottleneck for railroads as they muscle their way into Chicago; at one point, nearly half a dozen rail bridges crossed the canal. Only one remains in full-time service, but it sees heavy use, with multiple freight trains crossing it hourly.

Raw materials arrive primarily by boat; the wide mouth of the canal can handle full-size lake freighters and has docking space for several. Huge ore cranes lining both sides of the canal unload arriving ships.

One result of having such a huge complex is that outdated buildings and equipment are often abandoned in place and may stand for years, untouched, while business proceeds around them. It’s not like there are neighbors to complain! Large expanses of the site may deteriorate for years and even become overgrown.

Above: remains of an abandoned blast furnace alongside the canal in 2004. Already stripped of their support infrastructure, the hearths were dismantled shortly afterwards.

Above: remains of Inland Steel’s coke ovens and by-products processing plant. Inland ceased coke production in 1993, but the abandoned ovens still stand, with grass growing on the roof.

Long-abandoned ramp and trestle alongside Dickey Road. BP’s Whiting refinery looms in the background.

Half-demolished buildings can hang around for years:

An abandoned building in 2004.

The same building – most of it, anyway – in 2013.

Recycling steel is a major part of the contemporary steel business. Gondolas are stored here, full of scrap steel awaiting its fate in the arc furnace. The now-demolished Highway 912 overpass stands at right.

Legions of criss-crossing electrical lines speak to the vast power requirements of the complex.

And did we mention that there’s a significant work of architecture in the midst of all this industrial madness? The main office building on the site is a lovely 1930 work by Graham, Anderson, Probst & White. It’s an Art Deco beauty in red-brown brick, with floral cartouches atop each bay and twin towers punctuating its skyline.

The steel industry has changed dramatically since its last great domestic peak in the 1970s. Automation has vastly reduced the number of workers required to produce a unit of steel, leading to devastating unemployment in mill-dependent towns like nearby Gary. Evolving technologies have rendered many US facilities obsolete, leading to the kind of abandonment seen here and there on the Indiana Harbor campus. And international competition has required steel companies to be agile and flexible to survive. Outsourcing coke production was just one of a number of maneuvers by Inland and its successors to survive the times.

Rolling mill buildings. In these and other buildings, the newly formed steel is pressed or rolled into bars and other shapes of uniform thickness.

Forgotten Chicago offered a tour of the Indiana Harbor Canal in summer 2013, which sailed right through the middle of the plant; no word yet on when a repeat tour might be offered. Till then, I have more photos of the plant at my Flickr space.

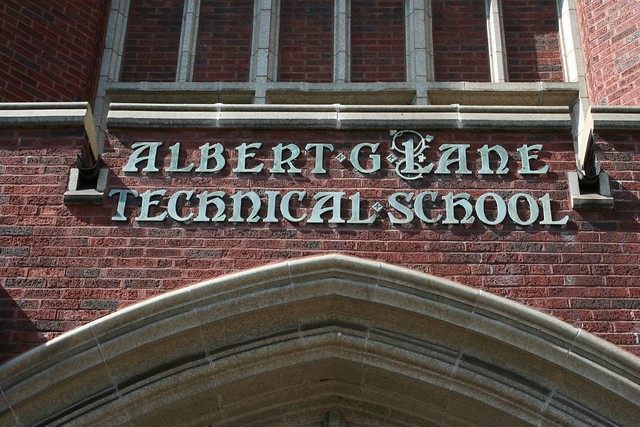

Lane Tech alumni, you got my attention.

You see, A Chicago Sojourn is a quiet little blog, highly specialized, written for a niche audience that’s pretty tiny. On a typical day, I get 100 to 300 page views. My best day ever, since moving to WordPress 18 months ago, was about 1,100 page views.

This week, y’all smashed that but good. Twice over and then some.

I don’t know through what channels my Lane Tech post from 2011 is getting bounced around, but clearly it struck a chord with lots of alums. I love big numbers as much as the next blogger… so by way of thanks, here’s a second look at Chicago’s biggest high school. Hopefully you’ll enjoy this outsider’s look at your alma mater. Maybe it will even let you see from a new perspective… literally!

If you’re flying into Chicago on a clear day and you get lucky, your flight’s approach to O’Hare airport will take you over the city’s northern reaches. The flight line is roughly aligned with Bryn Mawr Avenue, so if you’re on the left side of the plane you’ll get a sweeping view of the north side, including Lane Tech’s expansive campus.

It’s about two miles away, though, so if you really want a close look, you’ll need binoculars. Or a good zoom lens.

Likewise for the view from the other direction – looking north from the Sears Tower.

I haven’t been back to the school’s campus since my original visit, but I usually shoot lots more than I post, so I always have at least a few shots in reserve. Likewise, I didn’t do much research last time; this time I’ll dig a little deeper into the school’s history.

Lane Tech is named for Albert Grannis Lane, superintendent of Chicago schools from 1891 to 1898. Originally opened in 1908, Lane was soon moved into a new 1912 building at Division and Sedgewick. Faced with the great demand for industrial training, the building was soon overcrowded beyond reason, and plans for a replacement began in 1926. Once Lane moved out in 1934, the old building would be occupied by Washburne Trade School until 1958, then became Edwin G. Cooley High School, serving students from the nearby Cabrini-Green housing projects (and documented in the 1975 film Cooley High). Cooley closed in 1979 and was demolished sometime thereafter.

The new building’s planning and construction were long and drawn out. The School Board first began eyeing the land – previously a golf course and a brickyard – in 1926; the option of buying out nearby Riverview Park was rejected as too expensive. Architect John Christensen drew up plans which then sat idle for several years; foundation work began in 1930 but halted due to Depression-fueled funding problems. Construction sputtered along into 1931, with most walls going up, only to halt again due to money issues. Some creative financing by Mayor Kelly got building moving again in 1933. After two more years of construction, and a total cost of $6 million, the new structure was ready to receive its 7000 students.

The Albert G. Lane Technical School opened its new building on September 17, 1934. The event was heralded by an effusive article in the Chicago Tribune. On the opening day, some 6,000 students – all boys – marched from Wrigley Field to their new educational home, and were addressed by Mayor Kelly on the athletic fields.

The curriculum on opening day included a huge range of skills and training programs – from stone cutting to automotive repair and engineering. Dozens of labs, studios and workshops augmented the school’s classrooms, including an aviation shop with “sliding doors sufficiently wide to admit an ordinary airplane” as well as facilities for welding, forging & foundary work, and machine and motor testing. The superintendent of schools noted that the sectionalized coursework meant that students would leave Lane having learned something useful and adaptable to the job market – “no matter when they drop out”. Different times, indeed!

The legacy of that time still stands, greatly changed but still fulfilling its original mission. The focus on manual and technical training has been replaced with a more modern range of subjects, including a STEM focus; the student body is now highly diverse, including many children of recent immigrants.

Lane remained a boys-only school until 1972, when the first girls were admitted. The student body initially protested this break with tradition, with some 1,500 boys marching outside the school board building chanting “We don’t want no broads!” “Why are the girls coming to Lane? Because not being admitted violates their rights?” wrote one Tribune reader. “What about all of the boys whose programs will be curtailed? What about their rights?” Despite the trauma surrounding the idea, the school rather calmly went co-ed in 1972, one of the last in the city to do so. The Tribune recorded one anonymous student’s reaction: “We don’t mind girls in school here if they look pretty. We could do without the ugly ones.” Different times indeed!

Above: the exquisite library, the finest space of those I was able to visit. The lamps are especially beautiful in their detailing.

Below: the cafeteria, whose main attraction is a multi-paneled mural. It also has Gothic tracery in wood over the main entrance… a sharp contrast with the green-and-beige floor tile which looks like it walked straight out of 1959.

One thing that made Lane Tech so interesting to me was just how much it retains traces of the eras through which it has passed. The interior finishes span a range of ages – from original brick to Mid-Century floors and more. Incidental signs from many decades could be found, from the painted glass letters of the Faculty Dining Room to a simple, elegant Men’s Room sign, clearly dating from a long-vanished time.

And of course, there’s those wonderful World’s Fair murals. I could do a whole blog post just about them.

One commenter noted that I had not covered the stadium – a fair question. Truth be told, I wasn’t too happy with any of my shots of it; and to my dismay, I never photographed the front facade, which faces northward onto Addison Street.

It’s a peculiar structure, a horseshoe open to the south. The bleachers are permanent, built of limestone carved into Gothic forms, but they’re not especially big or towering compared to their length. In fact the whole thing looks like the base level of a gargantuan Gothic cathedral that never made it past the first story.

Planning for the stadium began in 1939, and it was dedicated in 1942. Built by WPA labor, the 5,000 seat stadium conceals a number of team, training and locker rooms under its stands. The dedication was combined with a music festival to make a rather elaborate and extensive event.

And since I’ve maybe got the attention of a few alumni – did anybody ever make it up into that big clock tower? It is a fascinating structure. Younger me – and present-day me, too – would have jumped at the chance to sneak inside that thing, especially to see what remains of the clock mechanisms.

A sojourn, as in the title of this blog, is a journey. And a journey has a start, various middle portions, some highs and lows, and then – inevitably – an end.

I am no longer living in Chicago. I am NOT done writing about it, not yet – but there will be an end, realistically some time in 2014. My writing on Chicago is almost entirely based on my own explorations and discoveries, and it’s impossible to continue without being out in the city, roaming its streets, savoring its details, uncovering its patterns.

I promise to close things out on a high note, and I’ll almost certainly set up a new blog and take up writing on some new subject afterwards. Till then, I’ll be cleaning out a long list of Chicago topics I’ve wanted to write about, as best I can without being local.

Stick around… there’s still plenty more to come.

This is the former MB Finanacial Bank building, 1200 N. Ashland Avenue, as it used to look.

And here it is today, after a CVS moved in some time around 2010.

Changes for the better – they unbricked the grand lobby windows! And the architectural goodness doesn’t end there. Just step inside…

No cruddy dropped ceilings or bland remodeling here – the CVS was simply dropped onto the existing banking floor, while all the architectural splendor around it was left intact.

The detailing of the bank lobby is magnificent. From the wood beam ceiling, to the plaster moldings, to the still-intact chandeliers, CVS has done a remarkable job of leaving well enough alone.

The outside of this place is something special, too. Bas relief sculpture lines the walls between the arched windows. Check out the signs of the age – from a ship’s wheel to a winged car wheel.

This handsome classical bank building was originally the Home Bank and Trust Company, designed by architects K. M. Vitzthum & Co. in 1925, and built at a cost of $1,000,000, with three floors of office space above. Home Bank was one of a spate of outlying banks opened in the years before the Great Depression, serving neighborhood needs – in this case the heart of Chicago’s Polish community. Despite merging with Northwestern Trust and Savings, the bank was killed off by the onset of the Depression in 1930, and a successor bank – United American Trust and Savings – only lasted another year.

In 1934, a stable legacy began when the Milwaukee Avenue National Bank opened its doors at Ashland and Division, supported by over 2000 depositors from the previous bank on the premises. With a 1946 name change, it became the Manufacturers National Bank of Chicago, with its name shortened to Manufacturers Bank by 1984. A 2001 merger with Mid-City Bank created MB Financial, who soon built their own headquarters downtown. The building was designated a city landmark in 2008; CVS opened its doors in 2011.

In the long-delayed Part Three of a look at Chicagoland’s moveable railroad bridges, we’ll visit all ten of Chicago’s vertical lift bridges – starting at the far south and moving north.

Vertical lift bridges consist of two towers housing counterweights and cable systems, with a moveable span between them which rises directly up when needed. They are often used for longer crossings and places where a waterway must be crossed at an angle. The towers, often reaching up to 200′ in height, are highly visible in Chicago’s flat landscape.

CSX / Joliet Railroad Bridge, Joliet – 1932

Nearly in the center of downtown Joliet, this bridge still sees occasional use by trains. It remains in the open position until needed by a train.

The bridge is one of a long sequence of moveable bridges lining the Joliet River as it passes through town. Barges necessitate the frequent opening of the bascule bridges seen in the distance.

Joliet Railroad Bridge at Bridgehunter.com

Canadian National Bridge – north of Joliet

Not easily accessible, this bridge sees frequent rail traffic on the CN main line.

CN Des Plaines River Bridge at Bridgehunter.com

Torrence Avenue Bridges – 1938, 1968

Two bridges standing side by side dominate the landscape of S. Torrence Avenue, visible from miles away. Much of the surrounding terrain is marshland and remains undeveloped, lending further prominence to these two massive structures.

The lowered bridge, recently rehabilitated and still in active use, is a road bridge, carrying Torrence Avenue over the Calumet River. It was built in 1938. In the photo above, it appears in its previous steel gray paint; post-renovation, it sports the common Chicago maroon.

The raised bridge is an abandoned railroad bridge, built in 1968. During renovation of the road bridge, the rail bridge was lowered and used as a bypass for the road.

Torrence Avenue Bridge at HistoricBridges.org

Chicago and Western Indiana Railroad Bridge at HistoricBridges.org

Norfolk Southern Bridge (originally Nickel Plate Road), Calumet River, 1971

A double-track rail bridge over the Calumet River, only a few hundred yards’ distance from the Torrence Avenue bridges.

Norfolk Southern Calumet River Bridge at HistoricBridges.org

Multiple bridges, Calumet River – 1912-15

A total of five bridges once spanned the river at this location – 4 vertical lifts, and a single bascule bridge. One of the lift bridges was demolished in the 1960s, and two more are abandoned, but they still form one of Chicagoland’s most impressive industrial sights.

In the view above, the one active bridge stands alone on the right; the gap marks the location of its lost twin. These two built for the Pittsburgh Fort Wayne & Chicago Railroad – eventually assimilated into its parent company, the Pennsylvania Railroad. The demolished bridge was removed in 1965; two workers were killed when a crane failed, dropping the span into the river.

At center are two abandoned bridges originally built for the Lakeshore and Michigan Southern railroad, which soon after became part of the New York Central. The Pennsylvania and the New York Central merged into Penn Central in 1968, rendering these two obsolete and leading to their abandonment. The bridge has since passed from Penn Central to Conrail to Norfolk Southern.

The left-most bridge is the half-destroyed bascule bridge, built by the Baltimore & Ohio Chicago Terminal Railroad.

The towers are around 190 feet high, capped with massive cable winding sheaves that are 15 feet in diameter. The Chicago Skyway bridge affords an excellent, if all too brief, view of the bridges’ upper workings.

The Calumet River Bridges at HistoricBridges.org

Canadian National / Elgin Joliet & Eastern Bridge 710 – Calumet River, 1974

Spanning the Calumet River just before it empties into Lake Michigan, this single-track span is the newest vertical lift bridge in the region.

It’s not clear that the bridge is abandoned, but it clearly sees very little traffic.

EJ&E Calumet River Bridge at Bridgehunter.com

Pennsylvania Railroad Bridge 458 – Chicago River, 1915

The heaviest lift bridge in the world when completed, this still-active bridge crosses the Chicago River south branch at Chinatown, carrying many Amtrak trains daily. It is raised twice a week during boating season.

Swing bridges are quiet curiosities – if it seems odd that a bridge should move, at least it’s only moving sideways.

Bascule bridges, by contrast, are utterly bizarre. If bridges aren’t supposed to move in the first place, then they really are not supposed to upend themselves into the air. That a flat sidewalk or roadway should become a vertical surface defies all logic and expectation.

Chicago’s roadway bascule bridges – including all the ones downtown – are elegantly slender, partly by necessity – crowded downtown streets don’t have a lot of room to spare. By contrast, the area’s numerous rail bascule bridges sport gigantic superstructures and enormous hanging counterweights, visually spelling out the defiant nature of their function – the titanic forces required to span a waterway, support a train, and occasionally turn the whole affair on its side.

Pennsylvania Railroad Western Avenue Bridge

Variously known as the 8-track bridge or the scissor lift bridges, this complex conglomeration of steel is one of Chicago’s most unique sights. Just south of Western Avenue, the “bridge” is actually four bridges standing side by side, supported by common foundations. Each originally carryied two sets of railroad tracks. The western two bridges – seen above, rusty brown from lack of maintenance – are now abandoned, with tracks removed. The eastern two, however, still see many freight trains a day.

The bridge type is known as a Scherzer rolling lift bridge – to open up, the entire span would literally roll back on the rounded arcs visible, pulled down by the massive counterweights hanging from the structure. Each bridge is a single-leaf structure, though the close spacing, alternating opening directions, and shared foundations have lead some sources to refer to them as double-leaf.

The 8-track bridges are no longer operable, and their motors have been removed. Curiously, there are no images online of the bridges in the open position, nor any indication of when the bridges last opened. Fixed in their closed position, they constitute the lowest bridge on the canal, with only 17 feet of clearance – a landmark by which boat clearances are measured by pleasure cruisers doing the various waterway circuits that pass through Chicagoland. Boats unable to pass below them must instead take the Cal-Sag canal to reach Lake Michigan.

The nearby Western Avenue road bridge was itself a lift bridge, with an impressively massive superstructure that has since been removed – see images here.

Further reading on the 8-track bridges:

Chicago and Alton Railroad Bridge

This smaller bridge sits next to an Orange Line El stop, and spans a short branch of the river that run southward before abruptly terminating north of Pershing Street. Bridgehunter.com dates it to 1906.

Further reading on the C&A Bridge:

St. Charles Air Line Bridge

Baltimore & Ohio / Chicago Terminal Railroad Bridge

The most monstrously huge of them all, this pair of lift bridges crosses the Chicago River just south of Roosevelt Boulevard.

The northern bridge – built for the Baltimore & Ohio and the Chicago Terminal Railroad, in 1930 – is long abandoned and permanently raised, the tracks leading to it long since vanished. (ref 1)

The southern bridge, originally serving the St. Charles Air Line Railroad, was built in 1919, moved and shortened in 1930, and still sees Amtrak traffic today. (ref 1) (ref 2)

The 1919 bridge was originally a few hundred feet east, as was the river itself. When the river was straightened, the 1930 bridge was built, allowing the older bridge to be moved alongside it without disrupting rail traffic. The older bridge was shortened at this time since it had less river to cross.

If you’re ever lucky enough to see this mass of steel in motion, you’ll discover that the heavy angled piece is actually hinged at both ends – the counterweight section hoists the bridge up not as a contiguous piece, but through this pivoting system. The city has posted an amazing video of it, and many other bridges in motion, here.

The abandoned 1930 bridge operated through the same system, known as a Strauss Trunnion after the engineer who designed it.

Further reading on the St. Charles Air Line Bridge:

Further reading on the B&O Bridge: HistoricBridges.org

Serving the Union Pacific North Metra line, the Deering Bridge was built in 1916, replacing an earlier swing bridge on the site. (ref)Further reading on the Deering Bridge: HistoricBridges.org

Serving the Union Pacific North Metra line, the Deering Bridge was built in 1916, replacing an earlier swing bridge on the site. (ref)Further reading on the Deering Bridge: HistoricBridges.orgKinzie Street Chicago & Northwestern Railroad Bridge

The other lift bridges are mostly far from the city center, in fairly out-of-the-way spots; not so the former C&NW bridge, which sits right in the middle of downtown. This bridge once served the industries near the lakefront, its tracks running under the Merchandise Mart to Navy Pier. The last customer was the Chicago Sun-Times; the bridge was lowered for paper deliveries to the printing presses. Since the Sun-Times closed up shop in the early 2000s (the site now replaced by the Trump Tower), this bridge has been permanently raised. (ref 1) (ref 2)

Further reading on the Kinzie Street C&NW Bridge:

Multiple bridges, at the Indiana Harbor Canal

At a narrow stricture point, multiple rail lines once crossed the Indiana Harbor Canal on their approach to Chicago – a total of ten lines on five bridges. Only two of the bridges remain in service today, carrying three tracks and seeing heavy freight traffic from BNSF and Norfolk Southern, as well as eastbound Amtrak trains.

The majority of trains pass over the Norfolk Southern bridge, the silver-whitish one in the foreground. Behind it, the bridge with the greenish tint is an Elgin, Joliet & Eastern bridge, now owned by Canandian National. The box girder bridge was previously the Baltimore & Ohio main line; the two trestle bridges in front of it carried the New York Central. (ref) The structures in the background are ore unloaders for the steel mill.

A sixth one was built in 2011 – a bright blue bascule bridge that directly serves the ArcelorMittal steel mills.

It’s barely visible above, but a clear shot may be seen here.

This fascinating group is difficult or impossible to reach without crossing a great deal of private property, or else taking a boat down the Indiana Harbor Canal – which, it just so happens, you can do this July if you take Forgotten Chicago’s Indiana Harbor Canal tour.

And just south of this group –

EJ&E Whiting Line Bridge No. 631

A much smaller and isolated bridge, still operable and in use. A small example of the Sherzer Rolling Lift style.

Further reading on the EJ&E Bridge: BridgeHunter.com

Baltimore and Ohio Railroad Bridge – at the Calumet River

This unfortunate stump of a bridge met a colorful end when a massive lake freighter hit it in 1988. The span was damaged beyond repair, and removed; only the counterweight portion remains in place today. (ref)

It stands alongside three vertical lift bridges… a topic we’ll cover next time!

It stands alongside three vertical lift bridges… a topic we’ll cover next time!

Further reading on the B&O Calumet River Bridge, including photos of the accident that destroyed it: HistoricBridges.org

One of my earliest impressions of Chicago, driving in from the north, was the string of grand churches visible from the Kennedy Expressway. I visited a few of them in my early explorations of the city. Then my attention wandered away, further afield to the mid-century suburbs and south side, and I never really got back to these near west side neighborhoods… until recently. Lately I’ve been on a mission to visit all these landmark houses of worship, a loose grouping that I have dubbed the Trail of Churches. A glimpse from the Sears Tower should show why the name fits.

At top-center, the domed roofline of St. Mary of the Angels. Below it, St. Stanislaus Kostka, with the highway swerving to avoid it. At far left, the low twin towers of Holy Trinity Polish. (Not visible, but close to Holy Trinity are the abandoned St. Boniface, and the very much active Holy Innocents.) And at bottom-center, just peeking into the frame, is the taller tower of St. John Cantius.

These four are among the city’s most spectacular religious buildings. Stick around and we’ll go on a tour of each one in turn. Today: St. John Cantius Catholic Church.

St. John Cantius (1893, architect Adolphus Druiding) was raised by the huge community of Polish immigrants that populated the near west side. Petitioning the nearby mother church of St. Stanislaus Kostka, they were granted their own parish in 1892. The work of raising a church building began at once; the final product was dedicated in 1898, flanked by a contemporary school and rectory. (Ref)

After its booming early years, the parish followed an arc of decline and revival. The downturn began in the 1920s with Ogden Avenue’s construction through the area, and bottomed out in the 1960s after the Kennedy was rammed through the neighborhood and innumerable residents fled. Decline began to reverse in the 1980s with the reintroduction of more traditional Mass attracting new congregants; the church’s fortunes have reached a magnificent new peak today as the building was renovated and restored in 2012. Today the church offers the traditional (pre-Vatican II) Mass in Latin, and has a strong emphasis on sacred music and art.

Architecturally, St. John Cantius Church is a hybrid of styles. The massive, dour exterior combines Classical elements – such as a flattened Greek temple front with quasi-Corinthian columns – with heavy, blocky stone that gives it some kinship with the Romanesque. At the entryway, “squashed” columns call out a lineage that includes ancient Greeks, Renaissance Italians, and contemporary Victorians. They emphasize the sheer massiveness of the building – as if at any moment they might snap and bring the whole thing tumbling down. Their smooth shafts are a moment of machine-like precision bursting out of a mass of roughly split rock. This sort of perversity was common among Victorian architects, who delighted in twisting expectations.

The interior lives up to the church’s official desigation of its style as “Baroque”. The modestly proportioned columms support pediments and seem a touch too large, intentionally “off” for dramatic effect. Huge arches spring from these dainty supports, a dazzling display of engineering.

Nearly every surface is gilded, sculpted, or painted. In a lesser setting it might be gaudy – but here, the glory of the decoration simply matches the grandness of the space.

The sanctuary is enormous. Soaring columns support vast round arches. The crossing is of tremendous proportions. The overall effect is of a open, lofty, airy space – a welcome respite during Chicago winters, which can leave a city resident feeling perpetually imprisoned in the small rooms of their house or apartment.

St. John Cantius is a golden space – it shimmers with browns and yellows, and blues and greens punctuate its murals and stenciling, but it is the golds which leave the deepest impression. The 2012 restoration has left the space in immaculate condition. Column heads and brackets are gilded in gold, and thanks to recent renovation efforts they gleam spectacularly. Even the stain glass reinforces the golden hued tones.

The reredos behind the high altar is a Mannerist confection, with clustered columns supporting a split pediment with a rounded arch pediment in the middle. A small round skylight brings light down onto it from above.

At the time of this writing, the old organ is being replaced by a new one; blue sheeting covers the balcony space where the new instrument will be installed.

The church is heavily laden with statues of saints and apostles; they are tucked away in the various side chapels and even in the stairwells.

The pulpit is a fine example of the church’s Baroque Revival style – its wooden stairs snake sensuously around a column, to an intricately carved wood speaker’s stand with an even more elaborate sounding board overhead.

Together with its school (1903) and rectory (1901), St. John Cantius Catholic forms a grand and amazingly intact group of turn of the century architecture.

It was some months back that, lost and trying to find my way back on track on my way to work, I stumbled across this New Urbanist development in north Glenview. Decent enough stuff, as suburban development goes, with plenty of sidewalks and bike paths, and easy access to the nearby Metra station. But then I came to the center of it all, and my eyes popped out a little bit.

This land, where shops and parking spaces and bike trails and a sizable wilderness preserve and park now dominate, was once a military airport.

And the International Style central control tower building has been preserved and adapted as the center piece of the new development. The surviving control tower is a portion of the Hangar One building; hangar sheds once stood behind each of the attached wings. Hangar One was built in 1929, by prolific Chicago architect Andrew Rebori, who also designed an expansion in 1940.

As an act of architectural preservation, it’s a remarkable feat. Such a utilitarian building would rarely be considered for preservation, let alone practical adaptive reuse.

The Navy air base at Glenview dates back to 1929, when it opened as Curtiss Field – intended to be the central hub for Chicago area air travel, and equipped with every modern amenity. It never took off, however; the Great Depression dealt a crippling blow. The Navy first moved in in 1936, and bought the field outright in 1940. With the United States’ entry into World War 2, the base became a major training center for aircraft carrier pilots, and was massively expanded in 1942. After the war it became a Reservist training center, a location for reserve naval aviators to maintain their skills and training. It also hosted Coast Guard and Marine units over the years, and served as a staging ground for the Chicago Air and Water Show.

Naval Air Station Glenview was closed in 1995 as part of a post-Cold War reorganization of the military, and the land turned over to the Village of Glenview for redevelopment. The runways and most buildings were demolished in the late 1990s; in their place rose The Glen Town Center – a collection of shops, businesses, parkland and residences. The project has not been a runaway success in business terms, owing to its somewhat obscure location, but design-wise it beats most of what’s around it hands-down.

An aerial view shows the two huge garages lurking behind the urbanist facades, where the hangar structures once stood.

The documentary site Abandoned & Little Known Airfields has a great set of historic photos of the air base while in operation and a thorough history, not to mention some colorful commentary on its closing, worth some editorializing: